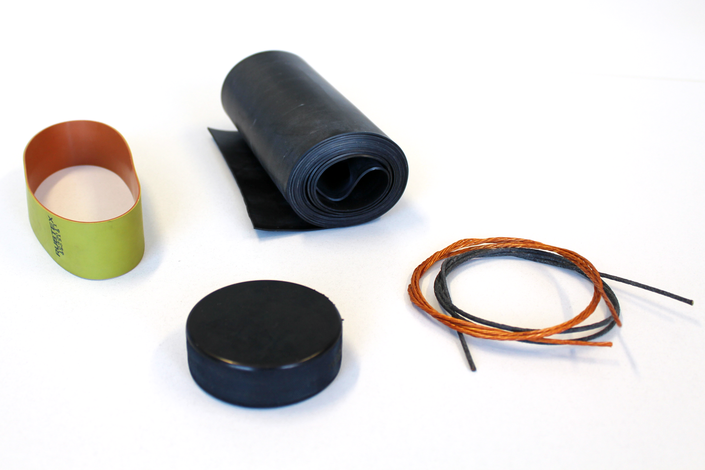

rubicon extruders fitted with special equipment and tools can be used to produce the most diverse of industrial rubber goods. Examples of products we can produce include round cords, rubber strips, granulate, rubber plates, as well as preforms for further processing in vulcanization presses, injection moulding machines and punching machines.

We also offer machines that are perfectly adapted for applications such as preheating compounds, producing rubber strips for feeding downstream machines, straining the rubber compound and blending compound batches.

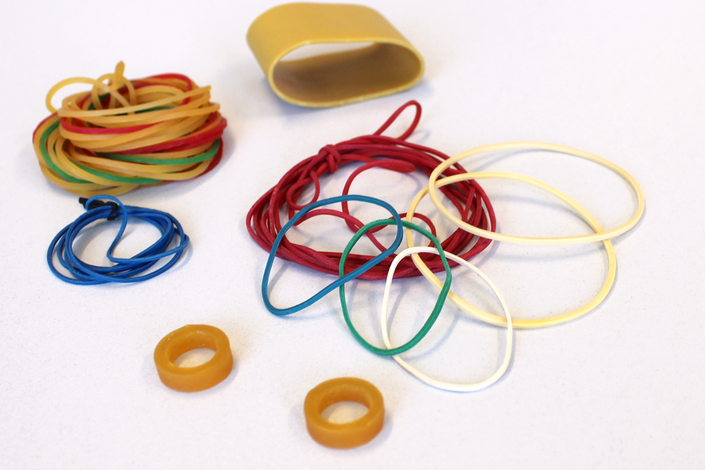

Rubber bands are widely used in industry, agriculture, medicine, as well as in offices and households. Owing to the high degree of elasticity required, they are mainly made from natural rubber, and are manufactured in countries that produce natural rubber. Most of the work involved in their production is still done by hand, especially in the vulcanization process. A large workforce is therefore required to carry out this work.

rubicon manufactures highly productive and efficient continuous extrusion lines for processing this material.

Deutsch

Deutsch

Français

Français

Español

Español

русский

русский