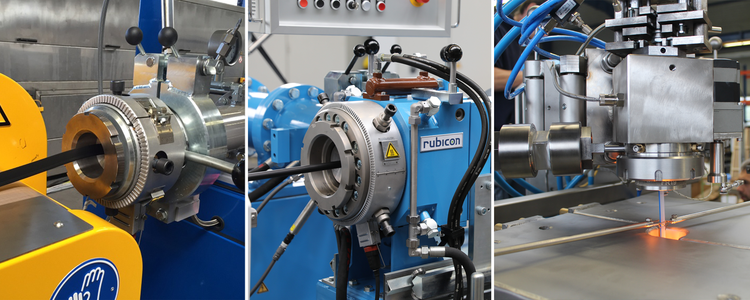

Extrusion heads

Be it for the extrusion of profiles or flexible hoses or the sheathing of cables- we offer straight-through heads or cross heads for use with our extruders for the most varied applications.

In addition to our standard extruders, we develop and manufacture special dies or tools to your specifications.

Many years of experience and continuous further development enable us to offer dies or tools that are easy to clean and come with optimal flow channels.

- straight extrusion heads

- cross heads

- sheathing heads (for hoses, for pipes and rollers, for cables)

- coextrusion and triplex heads

- preform heads

- slit tube heads

- rheometer heads

- special heads

Deutsch

Deutsch

Français

Français

Español

Español

русский

русский